- Homepage

- About us

- Film Laminating Machinery

- UV Coating / Screen Printing

- Label Machinery

- Hot Foil Stamping Machines

- Carton Gluers & Diecutters

- Folder gluers

- Miscellaneous

- Download Full Stock List

- Surplus Equipment Wanted

- Contact us

Manufacturers:

Global Print Finishing Equipment Ltd.

7 Appelton Court

Wakefield

West Yorkshire WF2 7AR

England

Tel: +44 1924 332425

Worldwide suppliers of print finishing & packaging machines

We supply:

New & reconditioned factory rebuild MK Autoplaten/die cutting/foiling machines

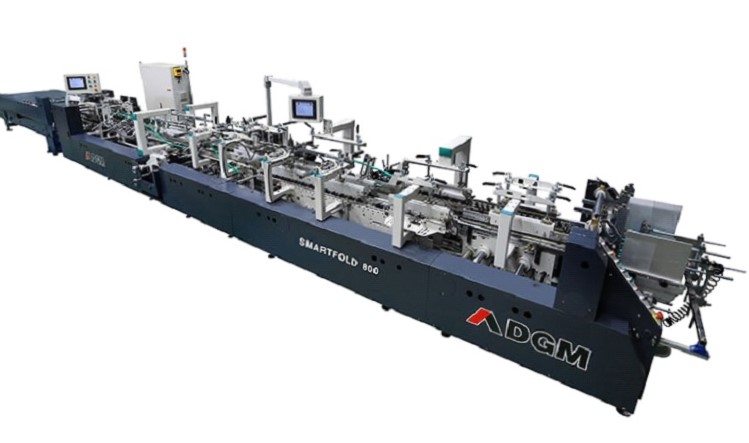

New DGM Folder Gluers (high speed) from 65cm to 3.2m width

New Fengchi board to board laminator from 145cm, 170cm & 220cm width

AVAILABLE IMMEDIATELY

Comprising:

Feeder, register section, demoulding section, Girobox section, folding & closing section,

Crashing roller module, trombone, conveyor & squaring device at conveyor

Carton 700g/m2

Corrugated flute type N, E & F

Speed max 500m/min, folded box thickness 15mm

Blank width max 1100mm

DGM TECHNOFOLD 1100 SL AUTOMATIC FOLDER GLUER

New machine

New generation of TechnoFold 1100 SL, 4 & 6 corner

Suitable for solid board & carton board boxes such as cosmetics, pharmaceutical packaging companies

Also for light corrugated board

With standard configuration for straight line boxes with prefolding

Processed cartonboard max 800gsm

Corrugated flute type N, E, F & B

Max speed 30m/min

Thickness of folded box max 12mm

Blank width max 1100mm

2001, GIETZ FSA870 HOT FOIL STAMPING MACHINE

Provision for diecutting

Max sheet 87 x 56cm, min sheet 28 x 21cm

Stamping area max 800 x 520mm

Pile height at feeder side 1120mm, delivery side 850mm

Mabeg feeder, 2 longitudinal foil feeds, 3 foil drives, high pile feeder

Ref (8904)

We supply the following types of used machinery:

-

Film laminating machinery from Billhofer and Paperplast

(water based laminators and thermal laminators / dry film laminators) -

UV coating machinery from Steinemann, Billhöfer and Sakurai

(varnishing machinery, uv dryers, surface coaters, roller coaters, spot coaters, spot varnishers) -

Printing machinery

(sheet fed offset and flexographic) -

Paper converting machinery

(paper bag making, pad making exercise books, die cutters, sheeters and slitter rewinders) -

Screen printing machines

Suppliers of large and small format, fully automatic screen printing machines - Label Machinery

-

Hot foil stamping machines

Hot foil stamping/gold blocking/embossing machines, either by the platen or cylinder process, from Bobst, Steuer, Gietz and Saroglia

Our engineers are widely experienced in the Printing and Paper Converting Industry. We are also available to move and relocate your machinery, either internally or to new sites. We will be pleased to offer references from customers where we have recently completed major installations.

Please see below our latest list of machines available (updated 20 October).

Spot coaters

Sakurai

- 1998 Sakurai MF80, 80 x 60 cm, high precision flat bed automatic screen printing press, 80 x 60 cm, min sheet 35 x 27 cm, print area 80 x 58 cm, automatic pile feeder, GTB hot and cold air dryer, fully automatic stacker, substrate thickness 0.1 – 3 mm (8931)

- 2014 Sakurai MS80A, 80 x 55 cm, min sheet size 350 x 270mm, automatic pile suction feeder with back separation, speed up to 3600sph, Natgraph UV dryer (2016), Natgraph automatic stacker (2016) (8871)

- 2002 Sakurai SC102AII, 72 x 102 cm, max print area 70 x 102cm, min sheet size 56 x 37cm, automatic stream feeder, Trumax UV dryer, automatic stacker (8945)

- 1997 Sakurai SC102AII, 72 x 102 cm, max print area 70 x 102cm, min sheet size 56 x 37cm, automatic stream feeder, sheet detector, UV dryer TX100, automatic stacker, 1 exposing unit & 15 frames included (8927)

- 2002 Sakurai SC102AIIi, 72 x 102 cm, max print area 70 x 102cm, min sheet size 56 x 37cm, automatic stream feeder, Trumax UV dryer, automatic stacker

- 2002 Sakurai SC72A, 52 x 72 cm, automatic pile suction feed with back separation, UV dryer,, Trumax fully automatic stacker, (8934)

- 1996 Sakurai SC72A, 52 x 72 cm, automatic pile suction feed with back separation, combination dryer, UV & hot air, Trumax fully automatic stacker (8930)

SBL

- 2003 SBL SHCUV 350, 72 x 104 cm, UV spot/full flood varnishing machine, max sheet size 72 x 104cm, sheet feeder, varnishing section (rubber or flexo plates), IR + UV dryer with 3 lamps, delivery (8781)

SPS

- 2006 SPS CYBERPRESS CP2, 720 x 1020 cm, min sheet size 320 x 450mm, screen size 1140 x 1280mm, automatic pile suction feed, speed up to 3,300sph, Natgraph twin UV lamp dryer, lamp curing width 1100mm (8835)

- 2012 reconditioned SPS VITESSA STAR G2, 79 x 104 cm, min sheet format 320 x 450mm, sheet thickness from 0.1mm to max 0.8mm, frame size 1270 x 1320mm, speed up to 3,400sph, fully automatic suction feed with back separation, UV drying unit, fully automatic stacker (8707)

- 2000 SPS VITESSA STAR G2, 79 x 104 cm, inline with SPS Turbostar combination dryer with Jet air & UV (2001, min sheet size 31 x 44cm, material thickness 0,1 - 0,8mm, speed 800-3000sph, screen frame size 1250 x 1320mm, Mabeg sheet feeder (8947)

- 1997 SPS G2, 75 x 106 cm, automatic pile suction feed with rear suction feeder, automatic sheet separator, combi dryers (3 x UV lamps 120 w/cm with 2 x heating sections and a cooling), gripper for cardboard. (8783)

- 1997 SPS VITESSA MULTISTAR G2, 70 x 102 cm, max printing size 67 x 100cm, fully automatic suction feed with back separation, max width 3mm IR, hot air, UV drying line (modular line that can be reduced), pile stacker delivery (8911)

Tymi

- 2006 Tymi Ustar 36, 80 x 110 cm, min 34 x 40cm, coating area 79 x 109cm, paper thickness 80 to 600 gsm, machine speed 6000 sheets/hour, total power 52.1 kw, stream feeder, 3 lamps curing equipments ( 3 X 9,7 KW)- total 29,1 kw, automatic system for creasing (8928)

- 2017 Tymi Ustar, 73 x 103 cm, min sheet size 34 x 40cm, spot or full surface coating, speed up to 8,800sph, extended delivery, 2 infrared units, de stacker & overlapping, Tymi SH1303 UV unit. (8788)

Surface coaters

Steinemann

- 2000 Steinemann Colibri 102, 104 x 142 cm, min sheet size 21 x 25cm, max speed 10,000sph, hot air unit/IR drying, sheet weight 70-600g/m2, UV varnish application 2.5-10g/m2 (8841)

- 1989 Steinemann Uvimat 86, 86 x 102 cm, min sheet size 22 x 28cm, Mirus pile suction feeder, 3 UV lamps, powder removal calender with heater, varnishing unit, Mirus automatic stacker, speed 10,000sph (8829)

- 2007 Steinemann COLIBRI 104, 74 x 104 cm, min sheet 21 x 25 cm, Mabeg automatic pile suction feeder, UV dryer, speed up to 10,000 sph, stock handled 70 – 600 gsm, fully automatic stacker, air knife (8857)

- 2006 Steinemann Colibri 74, 74 x 104 cm, Mabeg stream feeder coating unit with recirculating pumps, UV drying station, cooling station, deep pile delivery, vacuum pumps, extraction fans, speed 11,000sph, material 70-600gsm (8881)

- 2000 Steinemann Colibri 72, 72 x 102 cm, min sheet size 21 x 28 cm, single stream operation, sheet weight min 70g/m2, max 600g/m2, Mabeg sheet feeder, sheet cleaning unit, roller coater, UV dryer with cooling, sheet stacker, material 70 - 600 g/m2, max speed 10.000sph. (8943)

Board to board laminators

Lamina

- 2012 Lamina Blackline 1116FA, 110 x 160 cm, compact fully automatic paper to board laminator, automatic board feeder, automatic paper feeder, top sheet 130-450g/m, bottom sheet 0.6 to 10mm, glue unit, pressure belt, PLC control panel (8879)

Water-based laminators

Billhöfer

- 1987 Billhöfer FK76, 76 x 114 cm, min sheet size 21 x 21cm, Mabeg automatic pile suction feed, BAT 76 sheet separator, max mechanical speed up to 50m/min, for use with water based & thermal, adhesives, fully automatic stacker, (8851)

Paperplast

- 2007 Paperplast WD2 EVO, 140 x 104 cm, automatic film laminator, max sheet size 140 x 104cm, min sheet size 30 x 45cm, Samal bookmark, polyester cutting blade, automatic pile suction feeder (8819)

- 2007 Paperplast EVOLUTION, 102 x 165 cm, Samal automatic pile suction feeder, powder spray removal device, hot knife for polyester & metallised film, automatic blade, speed up to 100m/min (8856)

- 2001 Paperplast WD102, 102 x 114 cm, min sheet size 30 x 28 cm, Samal automatic pile suction feeder with back separation, powder spray removal device, speed up to 70m/min, for both thermal & water based lamination, fully automatic stacker, high speed machine with low power consumption. (8818)

- 2014 Paperplast DRY 80/102, 23 x 25 cm, min sheet size 760mnm, Samal feeder, side trim of unwind film, chrome calender, automatic separator with intelligent knife, automatic stacker with slow motion sheets. (8942)

Solventless laminators

Steinemann

- 2002 Steinemann LOTUS 102SF, 100 x 140 cm, Mabeg pile suction feeder, rotary hot knife, Mirus fully automatic stacker with blow-down system, powder spray removal device, sheet weight 100-600gsm, speed up to 70m/min, ideal for metallised film & polyester.

Thermal laminators

Autobond

- 2013 Autobond MINI 76SD-TPEM, 72 x 102 cm, automatic thermal laminator, 72 x 102cm, bottom separation, continuous suction feed with Heidelberg/Stahl suction drum, Autobond bump sheeter with digital sheet counter, anti-curl bar, perfector either single or 2 sheets in 1 pass, edge seal or flush cut, (8661)

Billhöfer

- 2000 Billhöfer ATS102, 106 x 143 cm, Billhofer/Ecosystem fully automatic thermal dry laminator (8839)

Cellcoat

- 2020 Cellcoat DIAMOND, 76 x 105 cm, min sheet size 210 x 297mm, flying knife with blade overlap for cutting of polyester & metallised film, speed up to 75m/min, sheet decurler, pallet stacker (8825)

Ecoscreen

- 2016 Ecoscreen Compact 76, 76 x 106 cm, min format 25 x 25cm, maximum format 88 x 114cm, automatic sheet feeder, max speed 60m/min, only run 150 hours (8888)

EcoSystem

- 2012 EcoSystem MODULO DRY 102, 102 x 142 cm, automatic Ecosystem feeder, vacuum table conveyor, lamination unit heated by water centralised system, chilling roller after lamination, automatic separator, automatic stacker, max speed 80m/min (8827)

- 2006 EcoSystem Compact 76, 76 x 106 cm, min format 25 x 25cm, maximum format 88 x 114cm, automatic sheet feeder, max speed 60m/min. (8922)

GBC

- 2006 GBC Centurion, 105 x 140 cm, Samal automatic pile suction feeder, automatic sheet separator, paper thickness 115gsm-1000gsm, fully automatic stacker. (8929)

Lamtex

- 2000 Lamtex Ti76, 102 x 72 cm, high speed, inline system, one man operation, sheet to sheet lamination, anti static device, HTB feeder with vacuum fed table, film perforation & slitter, air shaft, speed up to 75m/min, stock range 115-500gsm (8867)

- 2000 Lamtex T720, 76 x 102 cm, min sheet 24 x 29cm, max sheet weight 450g/2, min sheet weight 90g/m, automatic feeder, automatic sheet separator, vacuum lay board, swing arm with micro adjustment of film perforator, speed up to 30m/minute (8925)

- 1995 Lamtex T720, 76 x 102 cm, automatic thermal laminator, min sheet 24 x 29cm, automatic feeder, automatic sheet separator, vacuum lay board, swing arm with micro adjustment of film perforator, speed up to 40m/minute. (8702)

- Lamtex TI76E, 0, deep pile feeder, infeed unit, thermal laminator, heat exchanger, automatic sheeter, jogger delivery, 2 sided lamination, HTB feeder, vacuum feed table (8890)

Paperplast

- 2005 Paperplast DRY 40, 710 x 102 cm, Samal feeder, jogger table delivery, max speed 40m/min. (8833)

- 2001 Paperplast 76, 0 x 106 cm, min sheet 21 x 25cm, Mabeg automatic pile suction feed with back separation, automatic sheet separator, fully automatic stacker, speed up to 60m/min (8919)

Hot foil stamping

Bobst

- 1999 Bobst 142-E, 100 x 141 cm, hot stamping & embossing, (rebuilt by Mike King, USA 2011), max sheet size 1000 x 1414mm, uses Eagle Ecofoil system with 4 dancers collecting the used foil, die cutting capability, (8891)

Gietz

- 2001 Gietz FSA870, 87 x 56 cm, provision for diecutting, min sheet 28 x 21cm, stamping area max 800 x 520mm, pile height at feeder side 1120mm, delivery side 850mm, Mabeg feeder, 2 longitudinal foil feeds, 3 foil drives, high pile feeder. (8904)

Heidelberg

- Heidelberg CYLINDER, 54 x 72 cm, max sheet size 54 x 72cm, min sheet size 11 x 16cm, hot foil with honeycomb plate, 10 heating zones, embossing, sheet range 80gr, speed 2500sph (8859)

MK

- 2007 MK YM1050, 105 x 75 cm, hot foil stamping machine, 3 foil pulls, 20 heating zones, rewind, chase changer (8949)

- 2012 MK 920SS DUOPRESS, 92 x 65 cm, die cutting & foil stamping, 20 heating zones, min sheet size 360 x 320 mm, max die cutting size: 910 x 630 mm, max. stamping size: 900 x 600 mm, cardboard thickness: 90-2000 g/m2 and 0.1-2 mm, (8901)

- 2010 MK 20160 STE DUOPRESS, 76 x 106 cm, with stripping

- 2011 MK DUOPRESS 1060STE, 70 x 105 cm, in one pass with 2 stations, min sheet size 45 x 36cm, max die cutting size 1045 x 745mm, max speed 7,700sph, foil stamping, diecutting, stripping (8948)

Starfoil

- Starfoil HOT FOIL STAMPING CYLINDER, 73 x 104 cm, min sheet 290 x 400mm, foiling area 720 x 1038mm, feeder pile height 500mm, delivery pile height 850mm, max sheet thickness 0.65mm, 6 heating zones, max foil diameter 125mm, 2 foil units, number of lengths per programme – 3, PLC control, (8704)

Die cutters

Crosland

- Crosland Cauhe, 112 x 162 cm, hand fed die cutter, material solid board up to 2,500 microns, E & B flute corrugated (8880)

Heidelberg

- 2019 Heidelberg 106CSB, 76 x 106 cm, Promatrix, with blanking system, stocks up to 2000gsm/m2, impression tonnage 260, speed 7,500sph, counter impression 35 million, working hours 7605 (8944)

- 2018 Heidelberg Easymatrix, 76 x 106 cm, min sheet size 45 x 36cm, max feeder pile height 115cm, max delivery pile height 100cm, max cutting force 320T, 9,000 working hours, speed 7,500sph (8938)

Iberica

- 2004 Iberica TR-105F, 75 x 105 cm, speed 9000sph, Centreline-system (micrometric adjustment of the cutting plate), stripping, PLC computer, device for small size 35 x 40cm, non stop delivery (8905)

Sanwa

- 1997 Sanwa TRP 1060-SE, 74 x 106 cm, min sheet format: 330mm x 440mm, max die cutting format 735mm x 1050mm, sheet feeder, die cutting, stripping, pile stacker, material 0.1mm up to 5mm, die cutting force: 300T, machinery dimensions L x W x H: 5563mmx 2100mm, x 2193mm. (8936)

SBL

- 2012 SBL 1060CS ALPHA LUNA, 106 x 76 cm, automatic diecutting with stripping, min sheet size 40 x 35cm, max paper die cutting dimensions 105 x 74cm, die cutting pressure 300 tons, max die cutting speed 8000sph, gripper edge removal system, elevated. (8940)

Miscellaneous

Peroni

- 2017 Peroni SC1000, 13 x 13 cm, for rigid board boxes, cardboard size min 130 x 130mm, max 700 x 700mm, double feeder, grooving unit for U & V cuts & double dleivery unit (8906)

| LATEST OFFERS |

|---|

|

2011, MK DUOPRESS 1060STE FOIL STAMPING & DIECUTTING (8948)foil stamping & diecutter, in one pass with 2 stations, max sheet size 70 x 105cm, min sheet size 45 x 36cm, max die cutting size 1045 x 745mm, max speed 7,700sph, foil stamping, diecutting, stripping |

|

1987, BILLHOFER FK76 FILM LAMINATOR (8851)max sheet size 76 x 114cm, min sheet size 21 x 21cm, Mabeg automatic pile suction feed, BAT 76 sheet separator, max mechanical speed up to 50m/min, for use with water based & thermal, adhesives . |

|

2002, SAKURAI SC102AII SPOT COATER (8945)max sheet size 72 x 102cm, max print area 70 x 102cm, min sheet size 56 x 37cm, automatic stream feeder, Trumax UV dryer, automatic stacker |

|

2000, SPS VITESSA STAR G2 SPOT COATER (8947)inline with SPS Turbostar combination dryer with Jet air & UV (2001, max sheet size 79 x 104cm, min sheet size 31 x 44cm, material thickness 0,1 - 0,8mm, speed 800-3000sph, screen frame size 1250 x 1320mm, Mabeg sheet feeder, delivery stacker SPS autostack, |

|

2002, SAKURAI SC102AII SPOT COATER (8945),Max sheet size 72 x 102cm, max print area 70 x 102cm, min sheet size 56 x 37cm, automatic stream feeder, Trumax UV dryer, automatic stacker |

|

2019, HEIDELBERG PROMATRIX 106CSB DIECUTTER (8944)max sheet size 76 x 106cm, stocks up to 2000gsm/m2, impression tonnage 260, speed 7,500sph, counter impression 35 million, working hours 7605. |

|

2014, PAPERPLAST 2 SIDED 80/102 DRY LAMINATOR (8942)max sheet size 230 x 250mm, min sheet size 760mm, Samal feeder, side trim of unwind film, chrome calender, automatic separator with intelligent knife, automatic stacker with slow motion sheets. |

|

2012, SBL/ALPHA LUNA 1060CS AUTOMATIC DIE CUTTING WITH STRIPPINGmax sheet size 106 x 76cm, min sheet size 40 x 35cm, max paper die cutting dimensions 105 x 74cm, die cutting pressure 300 tons, max die cutting speed 8000sph, gripper edge removal system, elevated |

|

2018, HEIDELBERG EASYMATRIX DIECUTTING & STRIPPING (8938),max sheet size 76 x 106cm, min sheet size 45 x 36cm, max feeder pile height 115cm, max delivery pile height 100cm, max cutting force 320T, 9,000 working hours, speed 7,500sph |

|

1997, SANWA TRP-1060SE FLAT BED DIECUTTER (8936)max sheet format 740mm x 1060m, min sheet format: 330mm x 440mm, max die cutting format 735mm x 1050mm, sheet feeder, die cutting, stripping, pile stacker, material 0.1mm up to 5mm, die cutting force: 300T, machinery dimensions L x W x H: 5563mmx 2100mm, x 2193mm. |

|

1998, SAKURAI MF80 HIGH PRECISION FLAT BED AUTOMATIC SCREEN PRINTING PRESS (8931)max sheet size 80 x 60 cm, |

|

2002, SAKURAI SC72A SPOT COATER (8934)max sheet size 52 x 72cm, automatic pile suction feed with back separation, UV dryer,, Trumax fully automatic stacker, |

|

1996, SAKURAI SC72A SPOT COATER (8930)max sheet size 52 x 72cm, automatic pile suction feed with back separation, combination dryer, UV & hot air, Trumax fully automatic stacker |

|

2006, TYMI USTAR 36 (8928)max 80 x 110cm, min 34 x 40cm, coating area 79 x 109cm, paper thickness 80 to 600 gsm, machine speed 6000 sheets/hour, total power 52.1 kw, stream feeder, 3 lamps curing equipments ( 3 X 9,7 KW)- total 29,1 kw, automatic system for creasing |

|

1997, SAKURAI SC102AII (8927)max sheet size 72 x 102cm, max print area 70 x 102cm, min sheet size 56 x 37cm, automatic stream feeder, sheet detector, UV dryer TX100, automatic stacker, 1 exposing unit & 15 frames included |

|

2000, LAMTEX T702 AUTOMATIC THERMAL LAMINATOR (8925)max sheet 76 x 102cm, min sheet 24 x 29cm, max sheet weight 450g/2, min sheet weight 90g/m, automatic feeder, automatic sheet separator, vacuum lay board, swing arm with micro adjustment of film perforator, speed up to 30m/minute |

|

2006, ECOSYSTEM COMPACT 76 THERMAL LAMINATOR (8922)maximum sheet size 76cm x 106cm, |

|

1998, LAMINA MODEL 1116FA FULLY AUTOMATIC SHEET TO SHEET LAMINATOR (8920)max sheet size 1100mm x 160mm, min sheet size 200 x 350mm, top sheet 130-450g/m2, bottom sheet 250g/m2-10mm, corrugated from 0.6 to10mm, operating speed up to 3,000sph (dependent upon stock), auto substrate sheet feeder, auto top sheet feeder, precision gluing unit with auto glue application, laminating station with auto front & side registration system, pressure station, new PLC control system, down stacker. |

|

2001, PAPERPLAST 76 DRY THERMAL LAMINATOR (8919)max sheet size 76 x 106cm, min sheet 21 x 25cm, Mabeg automatic pile suction feed with back separation, automatic sheet separator, fully automatic stacker, speed up to 60m/min |

|

1997, SPS VITESSA MULTISTAR G2 SPOT COATER (8911)max sheet size 70 x 102cm, max printing size 67 x 100cm, fully automatic suction feed with back separation, max width 3mm IR, hot air, UV drying line (modular line that can be reduced), pile stacker delivery |

|

2002, STEINEMANN LOTUS 102SF SOLVENTLESS LAMINATOR (8912)max sheet size 100 x 140cm, Mabeg pile suction feeder, rotary hot knife, Mirus fully automatic stacker with blow-down system, powder spray removal device, sheet weight 100-600gsm, speed up to 70m/min, ideal for metallised film & polyester. |

|

2017, PERONI SC1000 AUTOMATIC ROTATING GROOVING MACHINE (8906)For rigid boxes, cardboard size min 130 x 130mm, min 700 x 700mm, double feeder, grooving unit for U & V cuts, double delivery unit |

|

2004, IBERICA TR-105F AUTOMATIC DIECUTTER (8905)paper size 75 x 105cm, speed 9000s/h, Centreline-system (micrometric adjustment of the cutting plate), stripping, PLC computer, device for small size 35 x 40cm, non stop delivery |

|

LAMTEX TI76E THERMAL LAMINATOR (8890)deep pile feeder, infeed unit, thermal laminator, heat exchanger, automatic sheeter, jogger delivery, 2 sided lamination, HTB feeder, vacuum feed table |

|

2001, GIETZ FSA870 HOT FOIL STAMPING MACHINE (8904)Provision for diecutting, max sheet 87 x 56cm, min sheet 28 x 21cm, stamping area max 800 x 520mm, ple height at feeder side 1120mm, delivery side 850mm |

|

2012, MK 920SS DUOPRESS DIE CUTTING & FOIL STAMPING MACHINE (8901)2 unit, 20 heating zones, max sheet size 920 x 650 mm, min sheet size 360 x 320 mm, max die cutting size: 910 x 630 mm, max. stamping size: 900 x 600 mm, cardboard thickness: 90-2000 g/m2 and 0.1-2 mm, max. corrugated thickness 4 mm, gripper margin 8-17 mm, max cutting force 200 tons |

|

2017, TYMI USTAR 102C UV SPOT COATER (8788)max sheet size 73 x 103cm, min sheet size 34 x 40cm, spot or full surface coating, speed up to 8,800sph, extended delivery, 2 infrared units, de stacker & overlapping, Tymi SH1303 UV unit. |

|

2016, ECOSYSTEM COMPACT 76 THERMAL LAMINATOR (8888)maximum sheet size 76cm x 106cm, min format 25 x 25cm, maximum format 88 x 114cm, automatic sheet feeder, max speed 60m/min, only run 150 hours |

|

CROSLAND CAUHE HAND FED DIE CUTTER (8880)Max sheet size 112 x 162cm, material solid board up to 2,500 microns, E & B flute corrugated |

|

2012, LAMINA MODEL 1116FA PAPER TO BOARD LAMINATOR (8879)max sheet size 110 x 160cm, automatic Board Feeder,automatic paper feeder, glue unit, pressure belt, PLC Control Panel, registration unit, pressing rollers, down stacker |

|

2006, STEINEMANN COLIBRI 74 SURFACE COATER (8881)max sheet size 74 x 104cm, Mabeg stream feeder coating unit with recirculating pumps, |

|

2010, MK 20160 STE DUOPRESSmax sheet size 76 x 106cm with stripping |

|

Rebuilt 2002, STEUER PZ104 FOILING CYLINDERmax sheet size 72 x 104cm, 3 foil pulls |

|

2018, LAMINA 1116FA PAPER TO BOARD LAMINATOR (8874)fully automatic sheet to sheet laminator, paper to board, max sheet size 1100 x 1600mm, top sheet 130-450g/m, bottom sheet 0.6 to 10mm, automatic board feeder, automatic paper feeder, glue unit, pressure belt, PLC control panel, registration unit, pressing rollers, down stacker |

|

2014, SAKURAI MS80A SPOT COATER (8871)max sheet size 800 x 550mm, min sheet size 350 x 270mm, automatic pile suction feeder with back separation, speed up to 3600sph, Natgraph UV dryer (2016), Natgraph automatic stacker (2016) |

|

2000, LAMTEX Ti76 THERMAL LAMINATOR (8867)high speed, inline system, one man operation, sheet to sheet lamination, max sheet size, max sheet size 102 x 72cm, anti static device, HTB feeder with vacuum fed table, film perforation & slitter, air shaft, speed up to 75m/min, |

|

2007, PAPERPLAST EVOLUTION FILM LAMINATOR (8856),max sheet size 102 x 165cm, Samal automatic pile suction feeder, powder spray removal device, hot knife for polyester & metallised film, automatic blade, speed up to 100m/min |

|

HEIDELBERG HOT FOIL STAMPING CYLINDER (8859)max sheet size 54 x 72cm, min sheet size 11 x 16cm, hot foil with honeycomb plate, |

|

2007, STEINEMANN COLIBRI 104 SURFACE COATER (8857)74 x 104 cm, min sheet 21 x 25 cm, Mabeg automatic pile suction feeder, UV dryer, speed up to 10,000 sph, stock handled 70 – 600 gsm, fully automatic stacker, air knife |

|

1989, SVECIA SM SEMI AUTOMATIC FLATBED SCREEN PRINTER (8849)max sheet size 900 x 650mm, min sheet size 280 x 200mm, dryer belt size 800mm, Truumax UV dryer, process chiller |

|

2013, AUTOBOND MINI 76SD-TPEM AUTOMATIC THERMAL LAMINATOR (8661)72 x 102cm, bottom separation, continuous suction feed with Heidelberg/Stahl suction drum, Autobond bump sheeter with digital sheet counter, anti-curl |

|

2000, STEINEMANN COLIBRI 102 SURFACE COATER (8841)max sheet size 104 x 142cm, min sheet size 21 x 25cm, max speed 10,000sph, hot air unit/IR drying, sheet weight 70-600g/m2, UV varnish application 2.5-10g/m2 |

|

2000, BILLHOFER/ECOSYSTEM ATS102 AUTOMATIC DRY THERMAL LAMINATOR (8839)Max sheet size 106 x 143cm |

|

2006, SPS CYBERPRESS CP2 AUTOMATIC SPOT COATER (8835)max sheet size 720 x 1020mm, min sheet size 320 x 450mm, screen size 1140 x 1280mm, automatic pile suction feed, speed up to 3,300sph, Natgraph twin UV lamp dryer, lamp curing width 1100mm |

|

2005, PAPERPLAST DRY 40 THERMAL FILM LAMINATOR (8833)max sheet 710 x 102cm, Samal feeder, jogger table delivery, max speed 40m/min. |

|

1989, STEINEMANN UVIMAT 86 SURFACE COATER (8829)max sheet size 86 x 102cm, min sheet size 22 x 28cm, Mirus pile suction feeder, 3 UV lamps, powder removal calender with heater, varnishing unit, Mirus automatic stacker, speed 10,000sph |

|

2012, ECOSYSTEM MODULO DRY 102 THERMAL LAMINATOR (8827)max paper size 102 x 142cm, automatic Ecosystem feeder, vacuum table conveyor, lamination unit heated by water centralised system, chilling roller after lamination, automatic separator, automatic stacker, max speed 80m/min |

|

2020, CELLCOAT DIAMOND FULLY AUTOMATIC SHEET FED LAMINATOR (8825)for thermal lamination, max sheet size 760 x 1050mm, min sheet size 210 x 297mm, flying knife with blade overlap for cutting of polyester & metallised film, speed up to 75m/min, sheet decurler, pallet stacker |

|

2007, PAPERPLAST WD2 EVO AUTOMATIC FILM LAMINATOR (8819)max sheet size 140 x 104cm, min sheet size 30 x 45cm, |

|

2001, PAPERPLAST WD102 AUTOMATIC FILM LAMINATOR (8818)max sheet size 102 x 114cm, min sheet size 30 x 28 cm, |

|

1997, SPS G2 SCREEN PRINTING LINE (8783)max sheet size 75 x 106cm, automatic pile suction feed with rear suction feeder, automatic sheet separator, combi dryers (3 x UV lamps 120 w/cm with 2 x heating sections and a cooling), gripper for cardboard. |

|

2003, SBL SHCUV 350 UV SPOT/FULL FLOOD VARNISHING MACHINE (8781)max sheet size 72 x 104cm, sheet feeder, |

|

1998, SAKURAI SC102DX ULTRA HIGH SPEED CYLINDER PRESS (8753)max sheet size 1050 x 750mm, min sheet size 420 x 297mm, max printing area 1020 x 700mm, UV dryer, hot air, Trumax fully automatic stacker. |

|

2015, CELLCOAT AUTOMATIC THERMAL LAMINATOR (8738)min sheet size SRA3, max sheet up to 9,000sph, fully automatic suction feeder, automatic delivery, post heat roller + post chiller roller. |

|

2012 RECONDITIONED, SPS VITESSA STAR G2 AUTOMATIC SPOT COATER (8707)max sheet size 790 x 1040mm, min sheet format 320 x 450mm, sheet thickness from 0.1mm to max 0.8mm, frame size 1270 x 1320mm, speed up to 3,400sph, fully automatic suction feed with back separation, UV drying unit, fully automatic stacker |

|

2008, STEINEMANN HIBIS 104 ROTARY SPOT & SURFACE COATER (8705)KBA pile suction feed with back separation, UV drying, UV flexo unit for UV or aqueous coating, Mirus fully automatic stacker, sheet weight from 80-400gsm, speed up to 7,300sph, full rotary screen making equipment |

|

STARFOIL HOT FOIL STAMPING CYLINDER (8704)max sheet 730 x 1040mm, min sheet 290 x 400mm, foiling area 720 x 1038mm, feeder pile height 500mm, delivery pile height 850mm, max sheet thickness 0.65mm, 6 heating zones, max foil diameter 125mm, 2 foil units, number of lengths per programme – 3, PLC control, electronic speed control, electronic pile lift. |

|

1995, LAMTEX T720 AUTOMATIC THERMAL LAMINATOR (8702)automatic thermal laminator, max sheet 76 x 102cm, min sheet 24 x 29cm, automatic feeder, |

|

2006, BILLHOFER EK TRENDLINE AUTOMATIC FILM LAMNATOR (8684)max sheet size 780 x 1140mm, min sheet 210 x 350mm, |

|

1987, SAKURAI SC102A SPOT COATER (8660)max printing area 70 x 102cm, automatic pile suction feed with back separation, 2003 Trumax UV dryer with 2 lamps, Sakurai fully automatic stacker, selection of frames. |

|

2012, MGI JET VARNISH 2D DIGITAL INK JET SPOT UV COATER (8514)digital ink jet spot UV coater, 52 x 74 cm, min sheet 21 x 30 cm, high capacity |

|

1995, HORIZON HT70 TRIMMER (8616)1998, SL40 tower |

|

2015, HORIZON PERFECT BINDER, MODEL BQ470 PUR (8615)4 clamps, PUR glue system, suction drum feeder, touch & work technology, perforating unit with 4 times scoring, max 320 x 320 x 65cm, min 145 x 150 x 1mm, cover size max 660 x 320mm, cover size min 225 x 135mm, paper thickness |

|

HEIDELBERG AUTOMATIC HOT FOIL STAMPING CYLINDER (8590)max sheet size 40 x 57cm, automatic pile suction feeder, 4 automatic foil unwinds |

|

2000, SPS VITESSA CLASSIC G2 AUTOMATIC SPOT COATER (8586)79 x 104cm, min sheet 32 x 43cm, automatic pile suction feed with back separation, Trumax UV combination dryer with hot air, Trumax automatic stacker, selection of frames |

|

2007 SHIKI FX1512 (semi-rotary offset) printermax printing width 345 mm, max printing length 320 mm, |

|

1996, LAMTEX ECO72thermal laminator, 72 x 102 cm, automatic pile suction feeder, automatic sheet separator, jogger table delivery, stock handled 90 – 450 gsm, speed up to 60 m/min (8554) |

|

2006, STEINEMANN COLIBRI 74 SURFACE COATER74 x 104 cm, min sheet 21 x 25 cm, Mabeg automatic pile suction feeder, sheet cleaning device, UV dryer, speed up to 10,000 sph, stock handled 70 – 600 gsm, air knife, fully automatic stacker (8558) |

|

2015, SAKURAI SC72AIIspot coating machine, 72 x 52 cm, min sheet 35 x 27 cm, max printable size |

|

For more information, contact us. |

-200x150.jpg)

-200x150.jpg)